Photovoltaik

At the beginning ETM was more regional, however it changed rapidly. Because of the high customer satisfaction and the optimally realized logistics, which the enterprise is very proud, soon an expansion into the surrounding countries succeeded.

ETM is a system supplier, that means from the planning of the system to the finished installation. Trained specialists ensure that your system is ready in a short time with professionallity and a high quality standard.

- Concept, offer, promotion processing

- Planning and implementation

- Operation, maintenance and service

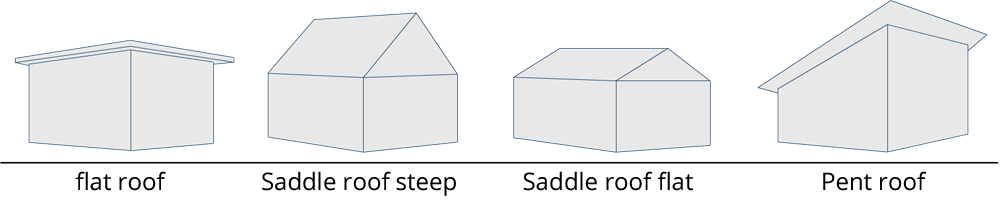

Executionforms

For every roof shape there are optimal possibilities to install a photovoltaic system.

Main types of roofing:

Roof tiles, roof tiles, roof tiles, corrugated sheets

There are tailor-made mounting systems for all roof shapes and roof coverings to fix the PV modules perfectly to the roof. Before installing a photovoltaic system, it must be checked whether the roof can absorb the additional load.

Floor mounting:

Fixed floor installation

Here the modules are permanently mounted on stands. The horizontal inclination is chosen so that the best possible efficiency is achieved.

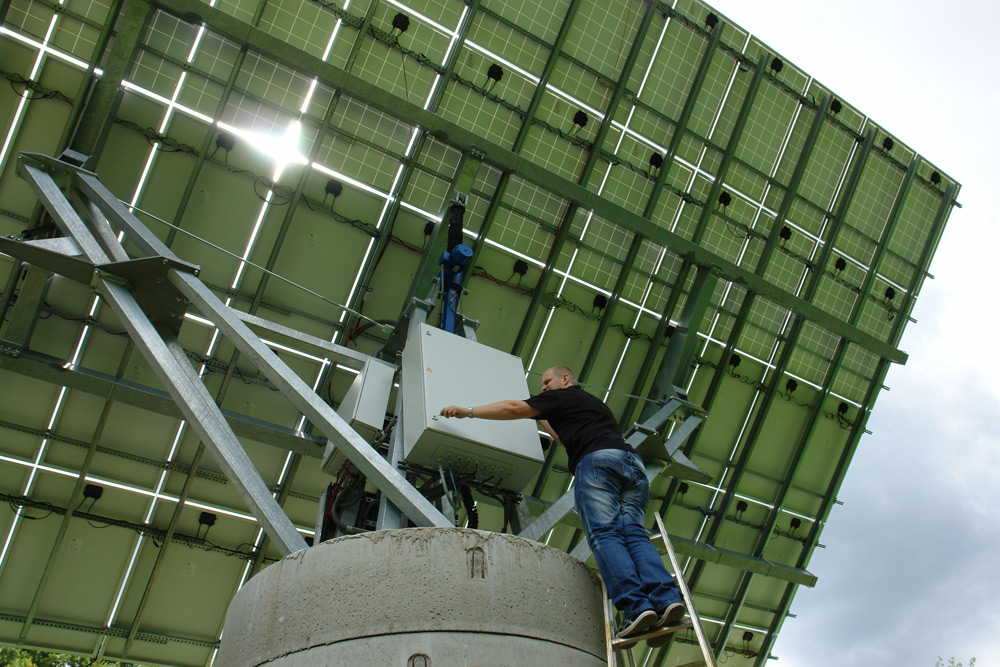

Floor installation with a tracking axis

Here, the angle of inclination of the modules is tracked to the position of the sun. As a result, the efficiency of the photovoltaic system can be increased by 15% to 20% compared to a fixed floor installation.

2-axis tracking systems (trackers)

Here, the PV modules are tracked both horizontally and vertically to the position of the sun so that the sunlight always hits the optimum angle.

As a result, the efficiency of the photovoltaic system can be increased by 30% to 40% compared to the fixed floor installation.

PV module verification

We check your photovoltaic system by means of a thermo flight drone

Every medium or larger photovoltaic system should be tested or cleaned at least once a year. It is also important to ensure the efficiency of the entire system during operation.

A thermal flight drone places the thermal imaging camera in the proper position over the module, ensuring optimal conditions for efficient inspection. With thermography, photovoltaic systems can be checked quickly and reliably. The drone is thus in most cases not only the best, but also the most efficient and often the only technical method for checking photovoltaic modules.

DOWNLOAD FLYER

SERVICES

- Diode function test

- Identification and location of heated cells (hotspots)

- Detection of string failures

- Detection of module failures (also partial failures)

- Checking the correct installation and wiring

- Detection of cell and glass breaks

- Check after bad weather or hail

- Detection of frost damage

- Verification of performance and wear

- Fast, safe and efficient!

No shutdown necessary

As a non-contact method, the photovoltaic thermography is carried out during normal daytime operation of the PV system. It’s not necessary to switch off the system. So no precious energy gets lost.

Review Recommendation

- Regular annual inspection

- Control in case of suspected underperformance

- Damage caused by environmental influences

Practical examples

Based on the temperature distribution on the surface of a photovoltaic system, faulty system components can be detected quickly. The investigated system must be in the load state during the thermography, ie generate electricity.

Normal temperature images

Ideally, with uniform irradiation, a very regular temperature image appears. Minor temperature differences of less than three Kelvin are either due to manufacturing tolerances of the silicon layer or external heat sources such as power-carrying junction boxes.

Power losses

By series connection of the photovoltaic cells within the modules, the principle of small cause applies - great effect. Measurements have shown that even a defective area of less than one percent of the total module area can result in a power loss of more than seven percent. How big the power losses are in detail can only be determined by an electrical measurement and depends on the type of defect.

Generally, it can be said that the patchwork pattern indicates an almost completely failed module. Cracked or cracked cells also result in drastic power losses. In case of conspicuous cell strands, the module performance is usually reduced only by the performance of the failed cell strands. Eminent single cells can, but need not necessarily lead to a reduction in performance. However, they should always be considered an indication of future failures.

© 2018 ETM Elektrotechnik Marquart GmbH

Press | TERMS | Imprint | Data protection